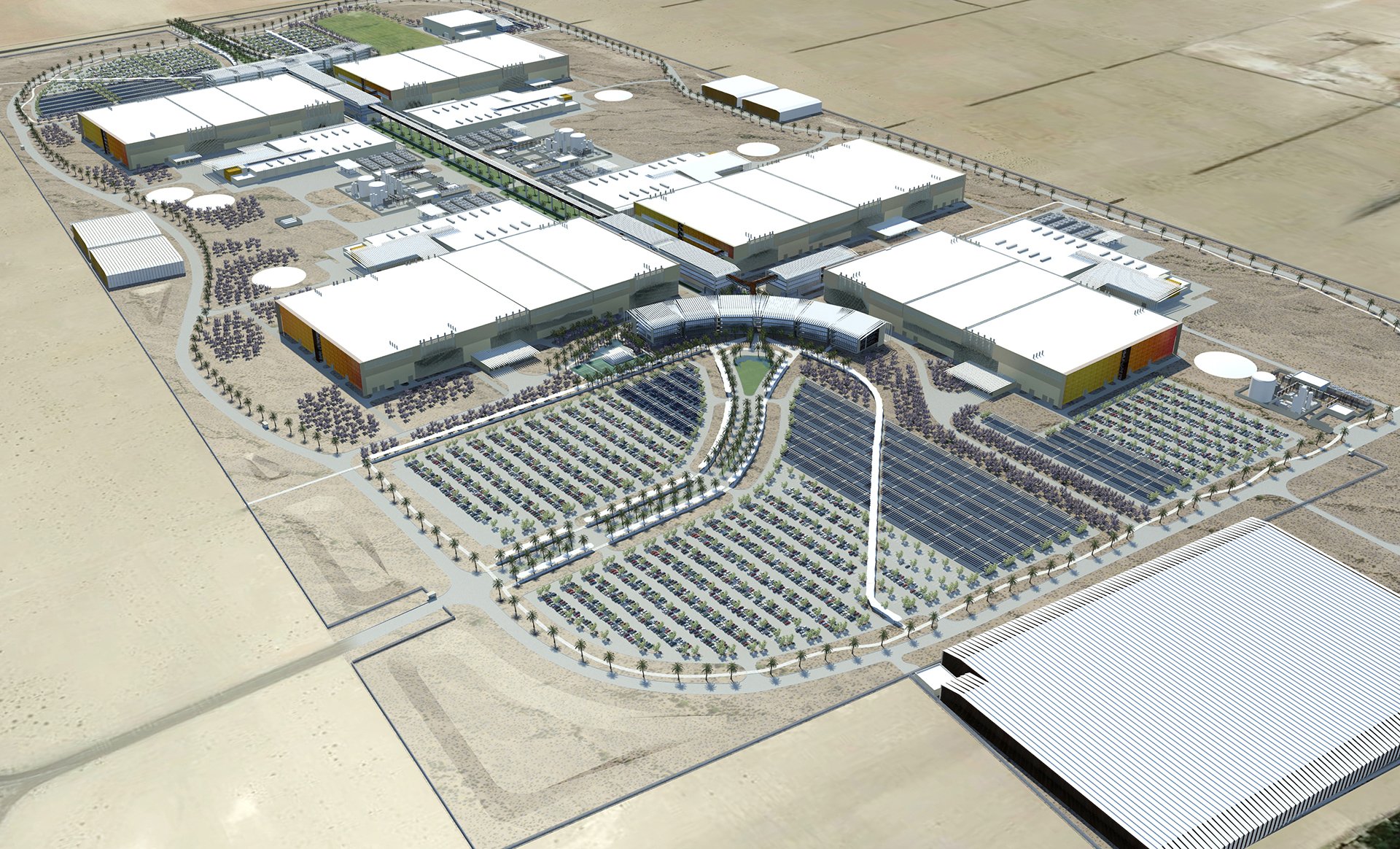

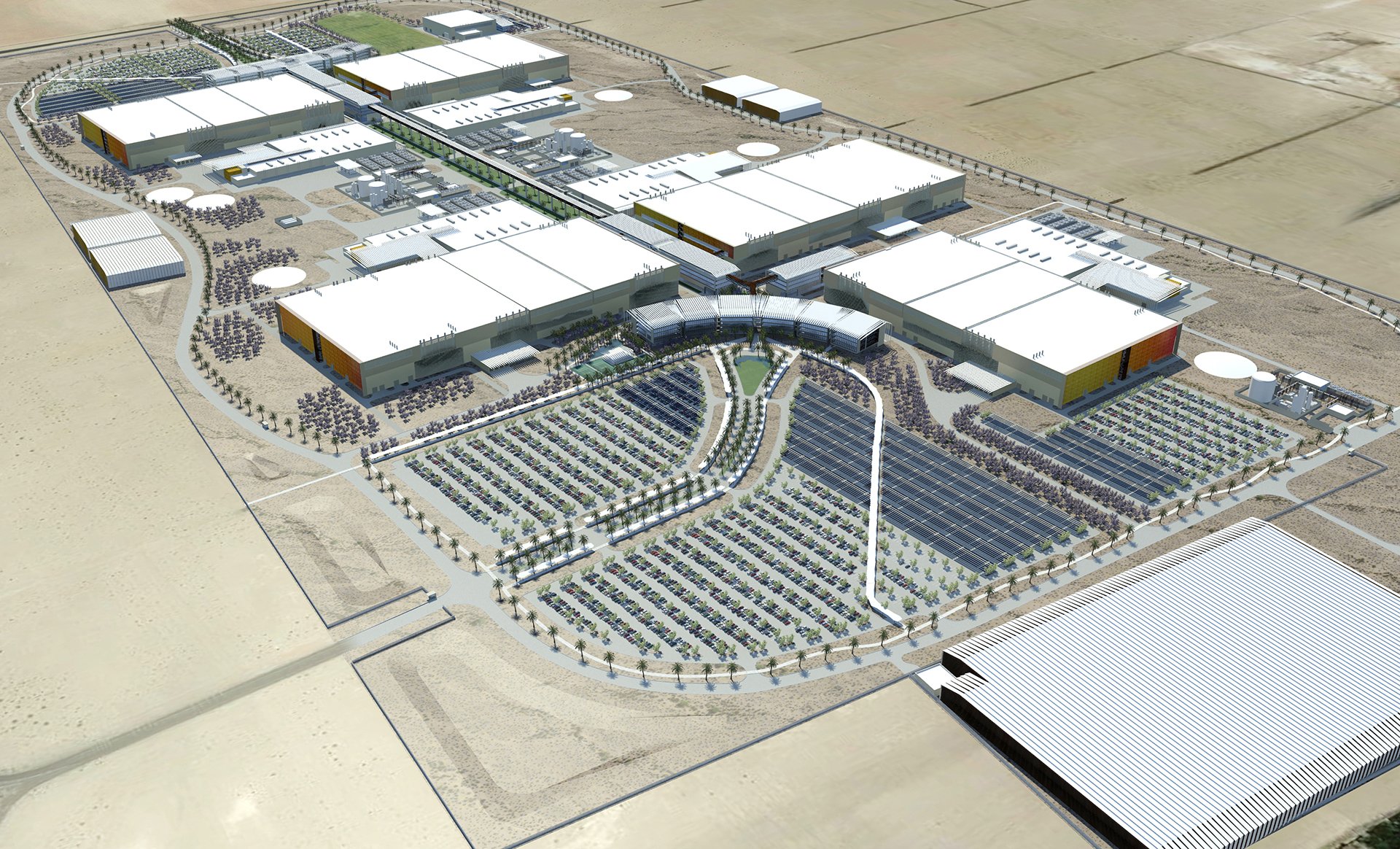

Abu Dhabi Semiconductor Fab Master Plan

Abu Dhabi, United Arab Emirates

To help fulfill the client’s vision to be the first truly global semiconductor foundry, CH2MHILL (in collaboration with Life Architecture + Planning) laid out a master plan for what would be the organizations flagship R+D and manufacturing campus. Critically, the campus symbolizes a bold investment in a country where intellectually sophisticated and high-paying jobs are sorely needed, and what’s more, jobs that are accessible and attractive to the country’s female population. Located on the eastern outskirts of Abu Dhabi, the 215 hectare (531 acre) site was envisioned as a “Fab Park” in order to create the highest quality working environment that will attract and retain the aforementioned sophisticated technological talent in this desert location.

The Fab Park was planned to be built out in five phases, each centered around a new Fab. At full build-out, the campus will embody an impressive 14.5 million sq. ft. of building stock. The first phase of the development will require an estimated investment of nearly US $8 billion alone.

Logistically, the campus was organized around the centralization of process support utilities and gas farms, allowing a critical redundancy to each of the Fabs and minimizing the overall campus utility runs. Staff functions are essentially divided into an east and west campus and connected via a central spine link bridge. This organization allowed the majority of vehicular traffic to be concentrated to the campus perimeter for ease of access and perhaps more importantly, to further reinforce the vital security of the manufacturing operations.

In terms of sustainability and natural resource utilization, building a semiconductor fabrication facility in the UAE is, to say the least, no easy task. Simply providing enough potable water and an uninterrupted power supply to the site will require streamlined organization and logistics in tight collaboration with the local utility and municipal authorities.

Beyond the manufacturing process, the campus is inherently designed to be a zero-scape environment, i.e., requiring no irrigation.

Inspired by vernacular traditions, strategically isolated landscaped oases will be provided however throughout the site, solely irrigated by the use of process waste water. Further, photovoltaic canopies will be utilized to not only produce enough energy to power all of the campus and building lighting, but will also serve as valuable shading throughout the vast expanse of parking required on-site. In terms of the buildings themselves, each of the facilities was envisioned to be designed to a 2 Pearl Estidama rating, essentially the equivalent of LEED™ Silver.